Prefabricated houses have become a perfect alternative in the face of rising housing costs. This situation is increasingly felt on the California coast and has led to Californian legislation to incentivise increased urban density while limiting the environmental impact of new construction.

This was perfectly understood by San Francisco-based designer Yves Béhar, who started a project designing "fully customisable accessory homes". One of the most attractive aspects of this type of houses is its versatility, not only in terms of price, but also in terms of size and personal aesthetics that each client provides.

Customised houses

The prefabricated housing project was presented at the latest Summit festival in Los Angeles, which takes place every year in November. Designer Yves Béhar launched these designs in collaboration with Plant Prefab, which aims to find an alternative to the housing problem without compromising on good condition, design, functionality, quality and personal taste.

The prefabricated houses project has been dubbed LivingHome 1 and has three versions available, with different layouts and roof styles. Flexibility and adaptation to all the details desired by the client stand out.

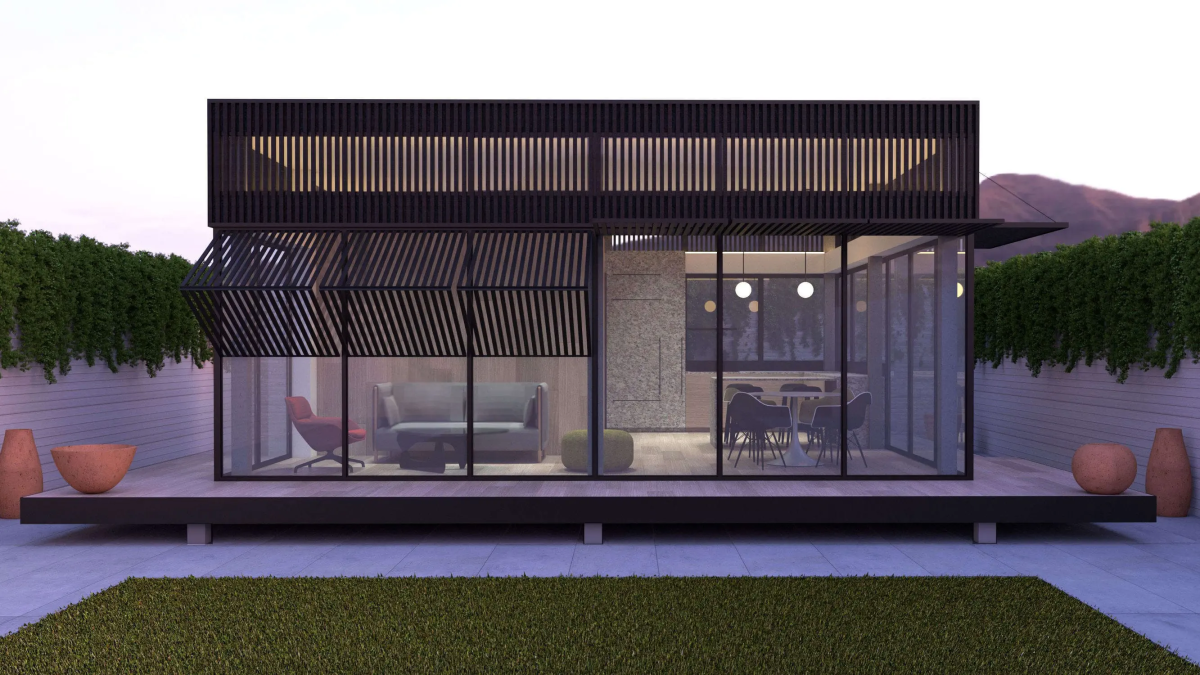

Thus, the size of the dwellings can vary between 23 and 112 m2, formed by grids of 1.20 m2. With this area, customers can opt for different spaces which in turn can be combined in size. This way, you can choose a full kitchen, a bathroom with shower, a living room, a bedroom or an office.

As far as roofs are concerned, two of the models feature flat roofs, especially suitable for hot, dry climates such as Los Angeles; while the third option features a pitched roof, designed for cooler, wetter climates such as San Francisco.

On the other hand, the layout of the windows is also very versatile and can be adapted according to the view or privacy of the interior. So it is possible to install panoramic windows, medium-height windows or skylight-shaped windows.

This whole concept of custom-made houses is part of the very essence of the project. In Béhar's words: "We are interested in the personalisation of prefabricated houses: people want their living environment to be a reflection of their specific living needs.

Efficient and environmentally friendly construction

In addition to being custom-built homes, these LivingHome YB1 prefabricated houses also consider sustainability and technology.

For example, at Plant Prefab, production rigorously adheres to environmentally conscious methods. The houses are manufactured and assembled "in situ", using helical metal piles as anchors to the ground. In addition, the wood panelling and cement panels are certified by the Forest Stewardship Council, an aspect that contributes to sustainability.

When it comes to home technology, also known as home automation, the design studio worked with a robotic furniture system from the company Ori, which specialises in implementing this technology in homes with limited space. In addition, Amazon's entry as an investor in the project aims to integrate the suite of voice-controlled devices, such as Alexa, into modular prefabricated homes at a more affordable price.

In short, the design goal of the YB1 LivingHomes, according to Béhar, "is to add population density through a variety of sizes and designs, built with a construction system that allows sustainable and efficient living in urban areas".